| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Snoopy

Guest

Joined: December 30 2005

Location: United States

Status: Offline

Points: 129

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Chiller closed loop Topic: Chiller closed loop

Posted: February 10 2006 at 10:35am |

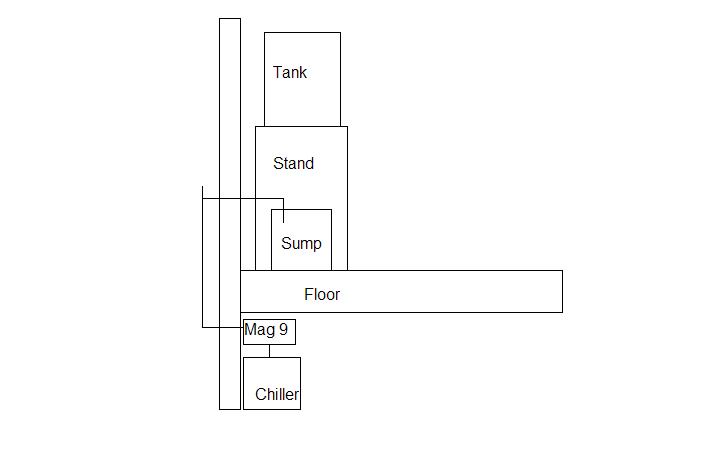

OK I broke down and bought a chiller. I'm evaporating so much water with my fans I have tons of condensation on my windows and will probably get mold if not controlled. Considering the house is 3 months old, the chiller is on it's way. I'm thinking of using a closed loop like I saw at the meeting to hook it up. Here is a drawing:  So one end will suck wter from the return chamber of my sump, and then pump it back into the refug chamber with the macro algae. Do I need a T joint after the wall like in the drawing for air intake? Do I need to have a cap for the T joint? Also with a Mag 9 will I need to prime the plumbing some how, or will it suck the little bit of air and pull the water down? I want it in the basement so I don't hear it, and the air is cooler down there. I was going to use a combination of PVC and flexible viynl tubing. Suggestions please! Thanks!

|

65 gal reef 40 gal sump/refg

2x250w AB MH 14k Phoenix

2x21w T5 actinic

Layton, UT

|

|

Gahlenfr

Guest

Joined: December 01 2005

Location: United States

Status: Offline

Points: 1061

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 11:25am Posted: February 10 2006 at 11:25am |

|

You will want to prime the pump so that you don't run it while dry. The T with a cap will allow you to do this. My question would be what is the height that the pump will push. If you figure minimum turnover of 10 times an hour, your pump with need 650gph plus to give you this type of circulation. I don't know how much is lost due to the chiller inline?

|

|

Snoopy

Guest

Joined: December 30 2005

Location: United States

Status: Offline

Points: 129

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 11:29am Posted: February 10 2006 at 11:29am |

|

The chiller needs 300 gph min and 700 max. I used the head loss calc at RC and i should run at ~550 gph with a Mag 9.5

|

65 gal reef 40 gal sump/refg

2x250w AB MH 14k Phoenix

2x21w T5 actinic

Layton, UT

|

|

dkle

Guest

Joined: February 15 2004

Location: Taylorsville

Status: Offline

Points: 1784

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 11:34am Posted: February 10 2006 at 11:34am |

One of the reasons why the temp is high is that you the water volume is small comparing to the lighting wattage. If you don't mind installing a large water tank/container in the basement, that should be able to help with the heat without a chiller. Also, you don't need to buy a big pump, just enough to circulate the water. Just a thought . .

|

|

If you can't bedazzle them with your brilliance, baffle them with your bs!

Dinhkim Le - Procrastinator extra-ordinare

|

|

jfinch

Guest

Joined: March 06 2003

Location: Pleasant Grove

Status: Offline

Points: 7067

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 12:24pm Posted: February 10 2006 at 12:24pm |

The beauty of a closed loop is that you'll get most of the rated (0 head) flow for that pump. The only head losses will be due to pipe friction. You should be ok on flow.

The tee is needed to prime the pump. If you drill a hole in the side of the sump you will not need the tee since it will then become self priming.

|

|

|

|

Snoopy

Guest

Joined: December 30 2005

Location: United States

Status: Offline

Points: 129

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 2:32pm Posted: February 10 2006 at 2:32pm |

|

After I prime it with the T, should I cap it? The sump is glass, and you could not get to the back :(. Thanks!

|

65 gal reef 40 gal sump/refg

2x250w AB MH 14k Phoenix

2x21w T5 actinic

Layton, UT

|

|

jfinch

Guest

Joined: March 06 2003

Location: Pleasant Grove

Status: Offline

Points: 7067

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 2:38pm Posted: February 10 2006 at 2:38pm |

|

Yes cap it. But better then a cap, imo, is put a 1/2" ball valve on top of the tee. Open the valve, fill, close valve, start up. Just pushing a cap on might allow air to leak into the pipe (causes bubbles) and a glued cap is too permanent. A valve will allow you to very easily reprime the pump if you ever loose the level in your sump.

|

|

|

|

Adam Blundell

Presidency

Joined: June 24 2002

Location: Davis County

Status: Offline

Points: 18526

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 2:57pm Posted: February 10 2006 at 2:57pm |

jfinch wrote: jfinch wrote:

Yes cap it. But better then a cap, imo, is put a 1/2" ball valve on top of the tee. Open the valve, fill, close valve, start up. Just pushing a cap on might allow air to leak into the pipe (causes bubbles) and a glued cap is too permanent. A valve will allow you to very easily reprime the pump if you ever loose the level in your sump. |

Hot dang why didn't you suggest that years ago. Every one of my stinkin' closed loops has had a threaded cap. Just the other day I had a long conversation with DNellans (not to mention all the talk at the last meeting with Corwondo and Pistonfister) about my new closed loop. In all that time discussing drilling the tank or going "up and over" we didn't really get into priming.

Ball valve on top is the best answer yet. Duh!

THANKS JON

Adam

|

|

Come to a meeting, they’re fun!

|

|

TNaisbitt

Guest

Joined: November 04 2005

Location: United States

Status: Offline

Points: 215

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: February 10 2006 at 3:23pm Posted: February 10 2006 at 3:23pm |

|

I just finished my closed-loop with a Mag 9 to drive my SQWD, but the

principle should be the same. I did find it helpful to put a ball

valve after the pump to help control the flow. The Mag 9 is so

strong that without the valve it was blowing things a bit too

hard.

I found a lot of closed-loop help at Melev's reef web site.

http://www.melevsreef.com/how_to_build.html

I too use the threaded cap at the top of the priming loop. It is

a pain, but the nice thing is that you know it's air tight. It is

also pretty inconspicuous looking hovering over the main tank.

The loop needs to be air tight to keep the pressure up. Is a ball

valve air tight? Probably close enough. That would be a

great way to go.

I used vinyl tubing as well for parts of my loop instead of PVC and it worked fine.

|

|

"Water which is too pure has no fish."

90 Gal Reef, 12Gal Nano Reef

West Jordan, UT

|

|